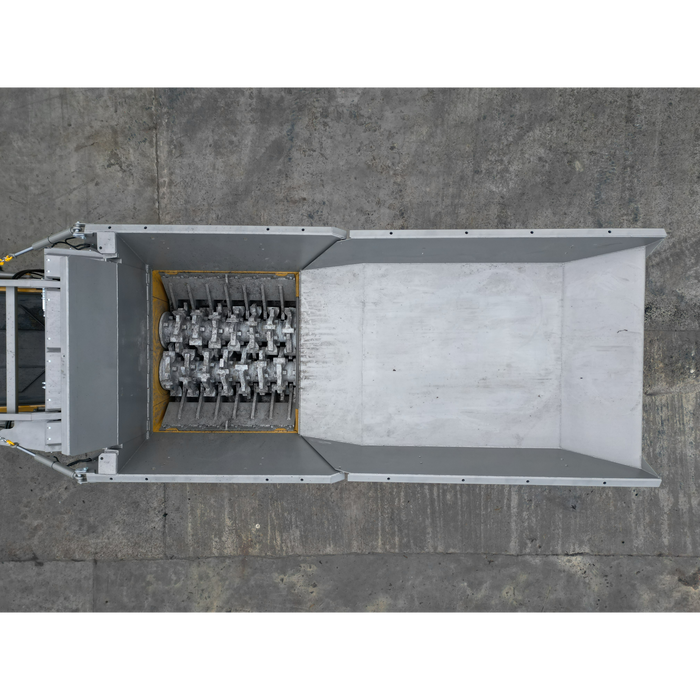

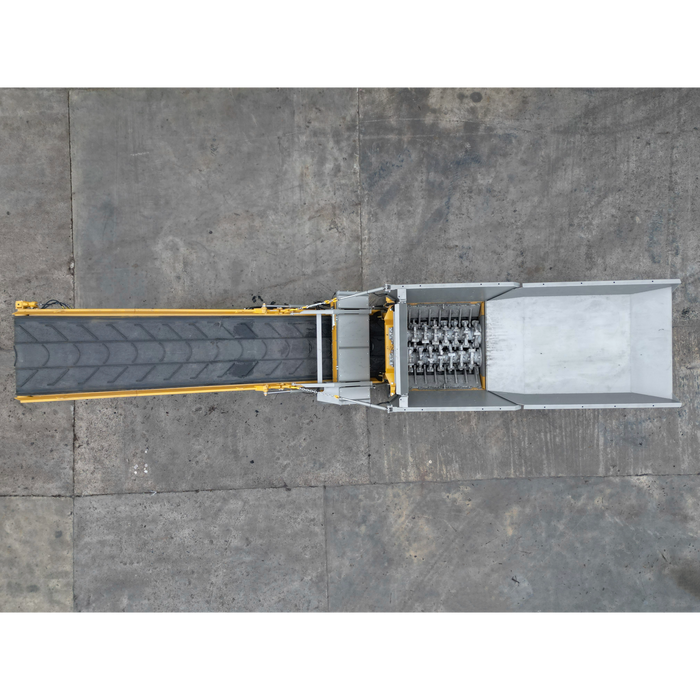

Olnova | Model 75 Primary Shredder | Tracked Diesel, High-Capacity Waste & Recycling Machine

- Manufacturer Warranty Included: You are guaranteed the full manufacturer warranty after purchase!

- Shipping & Handling Included: Processing Time 24-72 business hours. Manufacturer Direct Shipping

- Questions? Call (904)-671-3111 to speak to a live expert or email: support@constructiontoolsdirect.com

- 30 Day Satisfaction GUARANTEE

- No Sales Tax: No sales tax on your order except *FL.

Olnova Model 75 DK Primary Shredder – High-Power Tracked Diesel Machine for Industrial Waste Processing

The Olnova Model 75 DK is a heavy-duty, high-capacity tracked primary shredder engineered for demanding industrial waste, recycling, and demolition applications. Powered by a robust CAT C9.3B diesel engine delivering 415 HP (310 kW), this machine combines extreme mobility with powerful shredding performance. With multiple shredding modes, advanced remote monitoring, and superior material handling features, the 75 DK is built to maximize throughput while minimizing downtime.

Ideal For

-

Scrap yards

-

Recycling facilities

-

Demolition contractors

-

Municipal waste processing plants

-

Construction material recovery

The Olnova Model 75 DK delivers exceptional shredding power, operational efficiency, and worksite versatility—making it one of the most capable tracked primary shredders in its class.

** Contact us for wire transfer or ACH payment request via support@constructiontoolsdirect.com**

Features

-

High-Mobility Tracks – Exceptional maneuverability on challenging worksites.

-

CAT C9.3B Diesel Engine – 415 HP / 310 kW for consistent, heavy-duty performance with optimized fuel efficiency.

-

Four Shredding Modes – Three standard modes plus one individual mode for fine-tuned material processing.

-

Conveyor Belt Magnet – Efficient removal of ferrous metals for cleaner output.

-

Tilting Hopper – Simplifies loading and improves workflow efficiency.

-

Industry 4.0 Remote Module – Global performance analysis, customer feedback, and remote troubleshooting capabilities.

-

Radio Remote Controls – Full operational control from a safe distance.

Performance Output by Material

-

Light Mixed Scrap: 10 t/h

-

White Goods: 10 t/h

-

Industrial Waste: 45 t/h

-

Old Wood: 60 t/h

-

Household Waste: 50 t/h

-

Cable Drums: 40 t/h

-

Pallets: 50 t/h

-

Railway Sleepers: 25 t/h

-

Green Waste: 30 t/h

-

Root Stems: 35 t/h

-

Bulky Waste: 30 t/h

-

Paper Rolls: 15 t/h

-

Old Tires: 20 t/h

-

Aluminium: 12 t/h

-

Engine Blocks: 5 t/h

Specifications

-

Type: Tracked

-

Drive: Diesel Engine

-

Engine: CAT C9.3B

-

Power: 415 HP / 310 kW

-

Output Capacity: 15–60 t/h (material-dependent)

-

Input Material Size: 2500–5000 mm

-

Output Material Size: 150–400 mm

-

Shaft Speed: 23–43 rpm

-

Discharge Height: 5300 mm

-

Transportation Dimensions (L×W×H): 11360×2500×2870 mm

-

Operational Dimensions (L×W×H): 9710×2500×5800 mm

-

Weight: 22 t

-

Shaft Length: 2000 mm