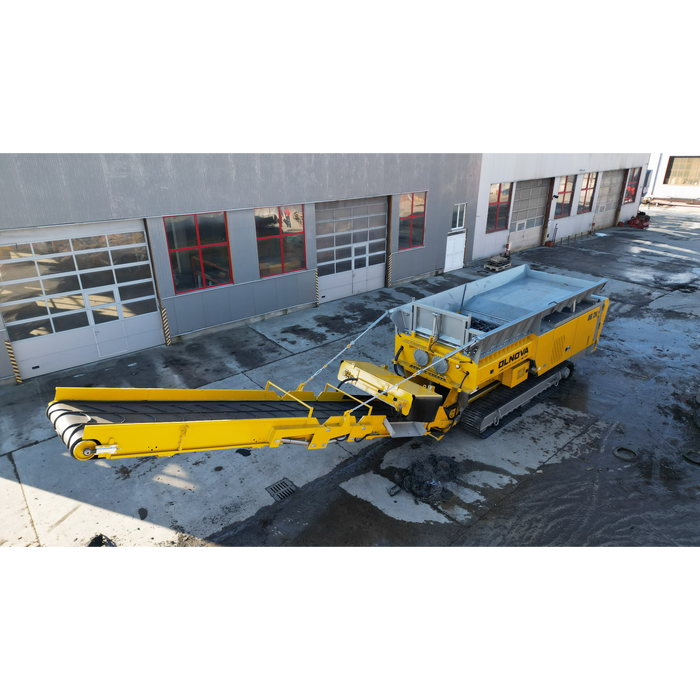

Olnova | Model 95 DK Primary Shredder | High-Capacity Tracked Diesel Machine for Heavy-Duty Waste Processing

- Manufacturer Warranty Included: You are guaranteed the full manufacturer warranty after purchase!

- Shipping & Handling Included: Processing Time 24-72 business hours. Manufacturer Direct Shipping

- Questions? Call (904)-671-3111 to speak to a live expert or email: support@constructiontoolsdirect.com

- 30 Day Satisfaction GUARANTEE

- No Sales Tax: No sales tax on your order except *FL.

Olnova Model 95 DK Primary Shredder – High-Capacity Tracked Diesel Machine for Heavy-Duty Waste Processing

The Olnova Model 95 DK is the most powerful tracked primary shredder in Olnova’s lineup, built for large-scale waste, demolition, and recycling operations. Equipped with a CAT C18 diesel engine delivering 760 HP (566 kW), this machine is engineered for extreme throughput, processing up to 200 tonnes per hour depending on the material.

Designed for high-volume applications, the 95 DK combines mobility, raw power, and intelligent operational control—making it ideal for processing mixed waste, construction debris, industrial materials, and bulky items.

Ideal For

-

Large-scale demolition projects

-

Industrial waste processing

-

High-volume recycling operations

-

Municipal and regional waste facilities

-

Automotive dismantling and recycling

With its massive throughput, advanced automation, and extreme durability, the Olnova Model 95 DK is the go-to choice for the most demanding waste processing and material recovery operations.

** Contact us for wire transfer or ACH payment request via support@constructiontoolsdirect.com**

Features

-

CAT C18 Diesel Power – 760 HP / 566 kW for unmatched shredding performance.

-

Tracked Mobility – Exceptional maneuverability for on-site repositioning in rugged environments.

-

Four Shredding Modes – Three preset programs plus one individual mode for custom material processing.

-

Conveyor Belt Magnet – Automatically separates ferrous metals for cleaner end products.

-

Tilting Hopper – Facilitates loading efficiency and adaptability to various feed materials.

-

Industry 4.0 Ready – Built-in remote monitoring for performance analysis, customer feedback, and troubleshooting worldwide.

-

Radio Remote Controls – Safe and convenient operation from a distance.

Performance Output by Material

-

Mixed Waste: 200 t/h

-

Industrial Waste: 150 t/h

-

Old Wood: 190 t/h

-

Construction Waste: 150 t/h

-

Cable Drums: 130 t/h

-

Railway Sleepers: 70 t/h

-

Tree Roots: 90 t/h

-

Bulky Waste: 110 t/h

-

Paper Rolls: 70 t/h

-

Old Tires: 50 t/h

-

Aluminium Waste: 40 t/h

-

Car Bodies: 40–60 t/h

Specifications

-

Type: Tracked

-

Drive: Diesel Engine

-

Engine: CAT C18

-

Power: 760 HP / 566 kW

-

Output Capacity: 40–200 t/h (material-dependent)

-

Input Material Size: 2500–5000 mm

-

Output Material Size: 150–400 mm

-

Shaft Speed: 13–29 rpm

-

Discharge Height: 5300 mm

-

Transportation Dimensions (L×W×H): 11360×3000×3305 mm

-

Operational Length: 15204 mm

-

Weight: 44 t

-

Shaft Length: 3000 mm